Jump on the Austin Hydrogen Fuel Cell Bus

In spite of the tizzy this week surrounding Bloom Energy’s $700,000 stand alone box of fuels cells which as AP reporter Jordan Robertson explained “will allow homes and businesses to generate their own electricity,” the lure of hydrogen fuel cells had fizzled over the past few years in the U.S.

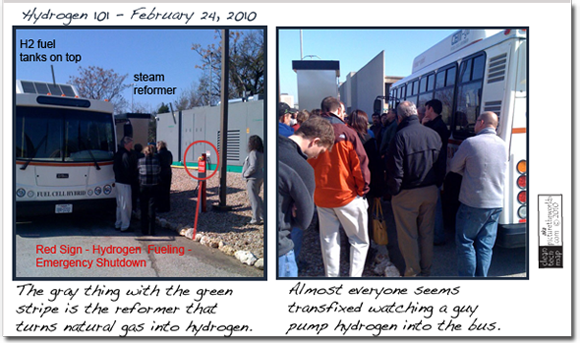

Not so for a couple dozen Austinites who jumped on the hydrogen bus this past Wednesday, February 24 at the UT J.J. Pickle Research Campus. This field trip on a bright and brisk morning, found them riding around to the back of the UT Center of Electromechanics building as the bus pulled up alongside a dark gray metal structure.

The Hydrogen 101 workshop was presented by HARC (Houston Advanced Research Center) Texas H2 Coalition in cooperation with Austin Energy's Central Texas Clean Cities and GTI (Gas Technology Institute) along with UT-CEM.

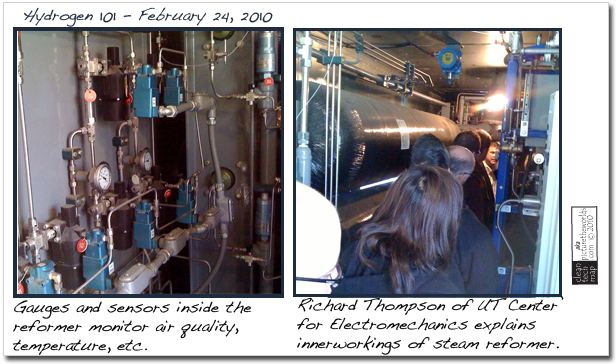

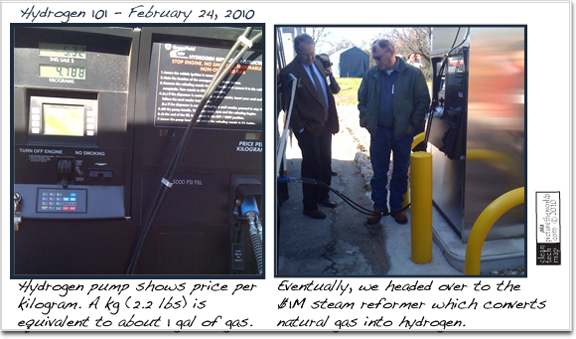

The first thing to get clear is that hydrogen is not an energy source: it's a carrier. The next thing to keep forefront is that 95% of hydrogen is produced from fossil fuels in steam methane reformers, one of which is marked in the left photo above. It was built at UT’s Center of Electromechanics in conjunction with performance lab Gas Technology Institute for $1 million.

Driving a hydrogen fuel cell vehicle produces no toxic emissions, and neither does reforming the hydrogen fuel from natural gas. But there are harmful emissions associated with processing the natural gas that hydrogen reformers use and from power plants when hydrogen is made using electricity. The electric vehicles running on hydrogen are cleaner than internal combustion engines running on natural gas, propane, gasoline, diesel or biofuels.

Hydrogen fuel produced from fossil fuels is known as brown or black hydrogen. The photos below show workshop attendees standing inside UT-CEM’s methane steam reformer that converts or 'reforms' natural gas to the hydrogen that supplies CEM's sole pump (shown in a photo later).

But hydrogen fuel can also be produced by electrolysis, which is sometimes called green hydrogen or renewable electrolysis. So for example, an electrolysis system can use elecricity from the grid, or according to the workshop, solar panels. A photo was shown of a fueling system capable of producing 12 Kg [sic] of Hydrogen per day or "only enough to run the controls" costing an estimated $1,250,000 which was developed by Wallingford, Conn.-based Distributed Energy Systems (which filed for bankruptcy in 2008 according to Ecofriend website, and could be construed to weaken the H2 defense).

Even the eye catching design and media blitz surrounding Honda's Torrance, California hydrogen prototypesolar pump for refueling hydrogen cars in your garage, at this time, is more media bark than payday bite.

Another prototype is modeled in NREL’s Wind-To-Hydrogen Project animation. The idea here, to combine wind and solar power to produce hydrogen, has drawn together turbine makers Bergey Wind Power and Northern Power Systems, BP Solar, Proton Energy Systems, Teledyne, Pressure Product Industries (hydrogen compression) and CP Industries (H2 storage tanks). The animation also shows the Hydrogen Engine Center (internal combustion engine), Plug Power (PEM fuel cell) and various components, some of which are vaguely recognizable in the photo of the inside the reformer included earlier in the post.

Still, even when hydrogen fuel is made from electricity from coal plants, hydrogen is "cleaner" due to the efficiency of the fuel cell vehicle, which, remember, has no emissions. Furthermore, fuel cell systems can generate electricity at up to 60% efficiency compared to a car’s gasoline engine’s 20% efficiency, which results in up to a 50% reduction in fuel consumption.

A type of analysis called "well to wheel" emissions calculates the life cycle emissions of fuels, whether from growing crops (including tractors, fertilizer inputs, etc) for making ethanol or drilling for petroleum and refining gasoline (refinery emissions, drilling emissions, etc.). Such analysis includes many fuel pathways, since some coal plants are not as dirty as others.

n: 0px; padding: 0px 0px 14px; font-size: 12px; line-height: 1.5; font-family: 'Trebuchet MS', Verdana, Arial, Helvetica, sans-serif; color: rgb(68, 68, 68);"

Texas produces 19.8% of U.S. production and consumes 15.2% of total U.S. natural gas (NG) consumption, more than any other state. Consequently, Texas also produces more hydrogen than any other state. (Seehttp://tonto.eia.doe.gov/state/state_energy_profiles.cfm?sid=TX.) The workshop did not clarify the stake Texas surely has in invigorating the hydrogen sector. A workshop presenter did pass along the statistic that two percent of current North American natural gas production could fuel 10,000,000 cars.

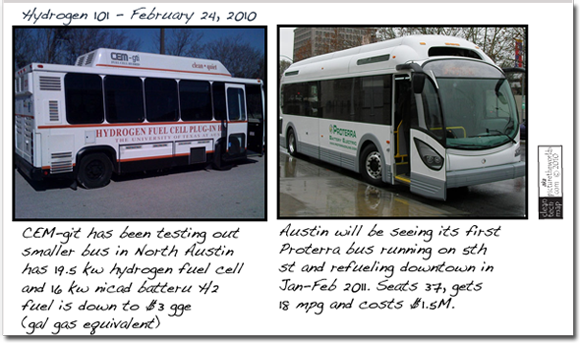

Currently there are 8.7 million natural gas vehicles worldwide, with 250,000 of these in the U.S. But natural gas vehicles produce higher emissions than hydrogen fuel cell vehicles. More promising, since 2002 the cost for hydrogen vehicle fuel cells has decreased from $275 per kW to $73 per kW. This means a 50 kW engine at $73 per kW works out to a $3650 electric motor cost. The DOE claims that the 2015 target of $30 per kW will be competitive with today’s vehicles (whether or not that's a positive indicator in the long run wasn't touched upon). The CEM-JIT bus in which attendees rode (shown in the left photo below), runs on a small 19.5 kW fuel cell stack-16 kW water-cooled NiCad battery and has been running a North Austin bus route during tests since 2009, getting somewhere around 18 mpg.

In contrast to the U.S., Europe, Russia and Japan have continued full tilt in development of hydrogen technology and infrastructure. The Japan government, for example, heavily subsidizes residential hydrogen fuel cell units for homes, similar in function but smaller in scale to the Bloom Box.

Closer to home, in Texas, the return of energy from fuel cells, according to the workshop, is in the 40-50% range, whereas Europe manages to achieve 80-85% return of energy, This is true in part because two of the largest gas producers in the world, Germany’s Linde Gas and Russia’s Gazprom have invested more heavily in research and development. In CIS states they’ve begun pumping excess heat and water, the two byproducts from hydrogen fuel cells, back through the architecture of their buildings. Finding ways to take advantage of the 'freeload', particularly water, said one workshop attendee, was incentivized by the need to circumvent existing water supplies which can contain high levels of lead. The point remains, however, that their hydrogen technology and systems are being more efficiently designed and more widely applied on a social scale, which ulmitately lead to economic beneifts which haven't yet been as fully realized realized here.

Today there are somwhere around 70 hydrogen fueling stations in the U.S., and one of these is located at the J.J. Pickle Campus, which might explain why everyone in the photo earlier on was crowded around to watch 5 kilograms (or about 2 gallons) of hydrogen get pumped into the bus. Another fueling station will be built downtown when the new Proterra hydrogen bus arrives, where it is expected to begin running on 5th Street in January and February of 2011.

A hydrogen fueling infrastructure requires only about 10% as many fueling stations as gas stations. A computer model has estimated that on the I-35 corridor from Dallas - Fort Worth, Houston, Austin and San Antonio there would need to be between 100-150 hydrogen stations. This is quite a small number compared to the 1,500 stations proposed in the comprehensive hydrogen fuel infrastructure plan supported by the German federal ministry for transport according to German website Hydrogen Mirror, which shows a build-out estimate cost of €3 billion euros.

According to California Fuel Cell Partnership (CaFCP) new estimates, the are projecting to have 49,600 FCVs on the road by 2015 – 2017. Most of these vehicles will be in the Southern California area (the region with the most hydrogen fueling stations) in the cities of Torrance, Newport Beach, Irvine and Santa Monica.

The focus in Northern California, in the San Francisco area calls for up to 60 fuel cell buses by 2014 and up to 700 cars. This mixture of large and small FCVs will mean that mixed H2 fueling stations will need to be built to accommodate both.

On a last note, hydrogen fuel cells cannot be recharged, and must be replaced after 5,000 kW. To the question what happens to a fuel cell when it dies, the official response, "I can't speak to that" was not nearly as hopeful as that of one attendee who quipped, "You mean fuel cell heaven." Platinum, one of various catalysts in fuel cells, is an element that has myriad environmental consequences both in how it is obtained, processed and disposed.

At the end of the half-day course, the presenters did not make clear how Austin's one-to-two-bus million-dollar-plus trial will drum up the business of getting more hydrogen vehicles on the road any time soon which could make it hard to catch up.